Mechanical areas to check - Page 3

Click any image to enlarge

Drive shafts

All Bay-Window vans use

double jointed drive shafts at the rear to transmit torque from the gearbox to

the wheels.

Again, the drive shafts are very strong like most parts on the Type 2 if a few

simple precautions are carried out. Check that the drive shaft gaiters are

intact. The gaiters protect the constant velocity joint from dirt and water and

contain the grease within the joint. If the gaiters have become loose or split,

it is likely that most of the grease will have been pushed out and water and

dirt entered, decreasing the life of the joint. You may be lucky with a damaged

gaiter where no damage to the joint has occurred and a fresh gaiter and grease

is all that is required.

Checking for wear is difficult. When moving off from rest, listen for a

knocking from the rear. Raise and spin the wheels, listening and feeling for

harshness. Grip the shaft and try to move it. Is there any movement? Even if

there is a little movement, as long as the joint is greased and covered they

can last many more years until they fail.

Clutch

The clutch should be light

and easy to operate. The bit point when raising the pedal should be between 1/2

to 3/4 of the way up.

To check the clutch, try pulling away from rest in 3rd gear. If the engine

speed rises but the vehicle speed does not, then the clutch is slipping and

will need replacement due to wear or oil contamination. It is quite common for

the rear crankcase seal to leak oil onto the clutch. This usually has the

effect of making the vehicle judder as you release the clutch as the clutch is

gripping and un gripping the flywheel.

The cost of a new clutch assembly is low - ranging from £53 - £91 depending on

engine type from

but involves the removal of

the engine to replace it, which is not difficult but takes a few hours and

really needs 2 people to complete safely.

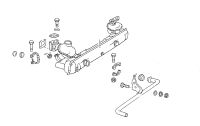

Gearbox

The gearbox rarely wears and

will take a huge mileage if the oil level has been maintained at the correct

level. The gearbox design is very similar to the gearbox used in the Beetle but

the 2 are not interchangeable. My 1974 van has completed 210,000 miles still

giving no signs of problems. Touch wood!!

Look for evidence of oil leaks, excessive noise, especially on the over-run and

jumping out of gear when moving. Difficulty in finding gears is usually down to

alignment of the shifter plate (

) under the gear stick or

wear in the bushes within the very long linkage. The rubber bush that connect

the gearbox to the linkage is the first to wear but it costs around £25 ( for 3

rubber bushes!!) and takes under 1 hour to change.

Engine

The Bay Window van used 2

basic configurations of engine. The T1 upright 1600cc. based on the Beetle

engine or later 1700,1800 and 2000cc. engines from the T4 saloon car range.

Both engines are air-cooled which means that oil

changes are of the upmost importance as the oil does the majority of the

cooling. Being air-cooled, the engines are noisy as they don't have water

jackets to insulate noise so listen carefully for abnormal noises. Noise from

the centre of the engine indicates wear in the big end bearings, while noise

from the head area could be tappets that need adjusting or wear in the rocker

assembly. To be able to identify these noises you need to know what a good

engine sounds like! It sounds simple but takes experience. Go to VW shows and

find an engine that is new or has been re-built and compare the noise to an

engine that you know is worn.

Both engines are air-cooled which means that oil

changes are of the upmost importance as the oil does the majority of the

cooling. Being air-cooled, the engines are noisy as they don't have water

jackets to insulate noise so listen carefully for abnormal noises. Noise from

the centre of the engine indicates wear in the big end bearings, while noise

from the head area could be tappets that need adjusting or wear in the rocker

assembly. To be able to identify these noises you need to know what a good

engine sounds like! It sounds simple but takes experience. Go to VW shows and

find an engine that is new or has been re-built and compare the noise to an

engine that you know is worn.

A good indication of wear on the 1600cc. engine is the

amount of movement at the crank shaft pulley that turns the fan belt. Hold the

pulley (engine off) and push and pull. There should only be the slightest

amount of movement. Any more movement than 0.15mm indicates wear in the rear

thrust bearing.

A good indication of wear on the 1600cc. engine is the

amount of movement at the crank shaft pulley that turns the fan belt. Hold the

pulley (engine off) and push and pull. There should only be the slightest

amount of movement. Any more movement than 0.15mm indicates wear in the rear

thrust bearing.

Look at the engine. Is it clean and tidy? Are all the cooling seals in place?

You should not be able to see the floor from within the engine compartment. If

you can see that seals or tinware are missing then the engine has probably over

heated at some point and damage may have occurred. Look for excessive oil leaks,

especially on the floor were the van is usually parked. All these engines tend

to leak compared to a modern engine as the crankcase is split in half which

cannot help. Look especially around the push rod tubes as these have a habit to

leak.

Start the engine from cold. Check for smoke. Blue smoke indicates burning oil

which means it could need new piston rings, pistons and barrels. Black smoke

indicates excessive petrol which means the carburetor is incorrectly adjusted

or worn. If left for too long, excessive petrol while also expensive, causes

the cylinder barrels to wear as protective oil is washed away by the petrol.

Take a look at the carburetor, does it look stained. Staining indicates worn

throttle spindles which allow fuel out and air in, resulting in poor

performance.

Check the fuel lines in the engine bay for cracks and missing clamps. When

looking at the engine you are looking for a general impression that it has been

well maintained. It should be clean, no bits of tape holding things together,

wiring placed tidily. Again, only experience can help here but the engine

should start easily, idle smoothly, not smoke and rev. freely when driving.

The VW air cooled engine is not the greatest engine for power but they are

reliable if looked after. If the engine does seem worn, do not be put off. Use

it as a negotiating point as all parts are still available. The 1600 engine is

much cheaper to repair than the T4 engine as parts are still being manufactured

by for VW in

Heater/Exhaust system

As

all Bay-Window Type 2`s are air cooled, heat for the cabin is recovered from

the hot exhaust gases by heat exchangers. The exhaust manifolds have fins cast

into the manifold body which radiate the heat from the gasses passing through

the inside of the manifold.  These fins are surrounded by a metal cover forming the

heat exchanger, which connects to ducts to the cabin interior. Later T4 engined

models had an additional fan that pushed air through the heat exchanger,

increasing the rate of flow to the cabin. The heat exchangers connect to the

exhaust system which is basically one large silencer and pipe work compressed

into a small area. Check for rust and holes visually on the heat exchangers.

You should be able to hear noise caused by holes on the silencer. Cover the

exhaust tail pipe with a cloth while the engine is running. The engine should

die as the exhaust gases cannot escape and pressure builds up. If there are any

leaks in the system you will here the exhaust gases escaping.

These fins are surrounded by a metal cover forming the

heat exchanger, which connects to ducts to the cabin interior. Later T4 engined

models had an additional fan that pushed air through the heat exchanger,

increasing the rate of flow to the cabin. The heat exchangers connect to the

exhaust system which is basically one large silencer and pipe work compressed

into a small area. Check for rust and holes visually on the heat exchangers.

You should be able to hear noise caused by holes on the silencer. Cover the

exhaust tail pipe with a cloth while the engine is running. The engine should

die as the exhaust gases cannot escape and pressure builds up. If there are any

leaks in the system you will here the exhaust gases escaping.

Heat exchanger cost around £60 each with original and better quality exchanger

costing around double. Original heat exchangers typically last longer and give

out more heat than the cheaper pattern varieties. T4 engined heat exchangers

are even more expensive which is also true for exhausts which vary in price and

quality from £40 to £200 plus for a stainless steel system.

T1 exhausts are a real pain to fit and can take 2-3 hours to fit as they never

go back together as they came off, plus all the nuts have a habit of rusting

solid.

Click here to return to previous page.